Frequently Asked Questions

From MoistureShield's company history to the materials that make up our wood composite decking boards, explore our FAQs to find out everything you need to know about MoistureShield.

We’re here to help answer your questions and solve your decking problems.

Frequently Asked Questions found

Yes, rail ends may be painted with any zinc rich primer or paint. For Fathom™ Steel Railing, we recommend Rust-Oleum Satin Canyon Black spray paint (code 249844) for Matte Black railing and Rust-Oleum Hammered Finish Brown spray paint (code 210880) for Hammered Bronze railing.

Yes, Fathom™ Steel Railing meets or exceeds all code requirements for installation on second story levels. It is important to always check with your local code enforcement office for the requirements on your project.

For Fathom™ Steel Railing, we recommend Rust-Oleum Satin Canyon Black spray paint (code 249844) for Matte Black railing and Rust-Oleum Hammered Finish Brown spray paint (code 210880) for Hammered Bronze railing. For minor scratches and application, we recommend spraying paint into the cap and applying with a small artist brush or cotton swab.

Gate end kits are used in conjunction with a level rail panel to create custom gates up to 48″ in length. Panels are cut down to size and gate ends slide onto the end of the panel. Pre-drill holes using a 5/32″ drill bit and fasten gate ends into place using hardware provided. Gate hardware kits (sold separately) must be used to attach gates to mounting posts to secure gate into place.

Yes, preassembled 34.5″ wide gates are available for Fathom™ Steel Railing and may be purchased for both 34″ and 40″ high panel sizes. We also offer gate end kits for use in creating custom-sized gates.

If you need to cut a section of steel railing, it is recommended that you use a jig saw that has metal blades or a portable band saw. ALWAYS wear safety glasses when cutting railing!

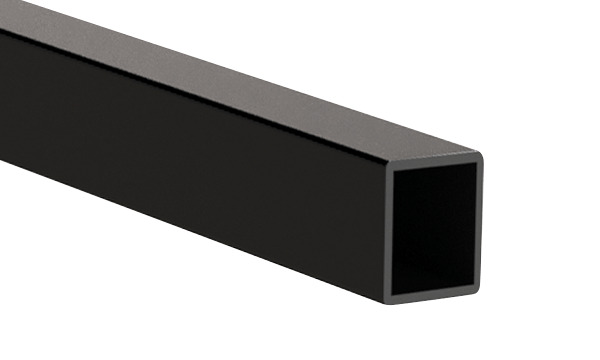

Blank posts are available for both stair and level applications when the preassembled post is not ideal. This is most common with angled rail sections and/or stairs. Blank posts are 2” or 3″ square steel posts that include pre-attached aluminum post caps, leveling shims and two-piece trim rings. Blank posts do NOT include mounting brackets (brackets must be purchased separately).

There are four types of posts available for steel railing: end, mid (line), corner and blank. The end, mid and corner posts are preassembled for applications with either a 2” or 4” bottom space. End, mid and corner posts come standard in both 2” and 3” square steel posts that include pre-attached level brackets, pre-attached aluminum post caps, bracket covers, leveling shims and a two-piece trim ring.

Fathom™ Steel Railing panels are 1/4″ shorter than the nominal dimension. For example, an 8’ x 36″ panel is actually 95 3/4″ long. Once installed, accounting for bracket size, space between posts will be 96″.

Yes, but only when the stair section is level (0 degrees). Steel stair rail panels are designed for installation at angles ranging from 0 to 38 degrees. The higher the pitch of the rail, the closer together the spacing becomes. At maximum pitch, baluster spacing becomes about 3”.

225 pounds of tension is recommended for each row of cable.

Yes, but the mid baluster supports that come with cable beam kits cannot be used. Rather, space fascia posts 4’ apart for fascia cable applications.

Yes, but angles other than 0 or 90 degrees require double posting.

A maximum of 2 corners or 40 ft of cable through a corner is allowed before needed to double post. If you have more than 2 corners in a run you will need to choose a location to double post. If you have a corner post and more than a 40’ run of cable, you will need to double post that corner. This allows the tension required to be achieved.

Double post at the top of the stairs. Stair posts were engineered so that the cable would not hit the nose of the stairs, and also prevent a 6” sphere violation.

Dings or scratches can be repaired with color matched touch-up paint. For small areas, use our .5-ounce bottle with brush applicator. For larger areas, use our 12-ounce aerosol can.

Yes, you can use the 4 1/4″ x 4 1/4″ x 108″ columns with mounting kits for both the top and the bottom of the column.

Compass Aluminum Railing can be cut with most saw types. When using a power miter saw, a high tooth count (80 or more) carbide tip is best. Be sure to have the blade up to speed before beginning your cut. Hack saws and other saws with metal cutting blades will also cut aluminum railing.

Yes, Compass Aluminum Railing meets or exceeds all code requirements. It is important to always check with your local code enforcement office for the requirements on your project.

Yes, MoistureShield Railing offers two choices to mount Compass Aluminum Railing on concrete. You can core mount in the concrete using either of our face/core posts or use our flush mount post with a high-quality concrete anchoring system.

Compass Aluminum Railing level rail kits are designed to install up to a 5-degree slope, which is the maximum pitch allowed by code. Use level rail sections and stair rail brackets.

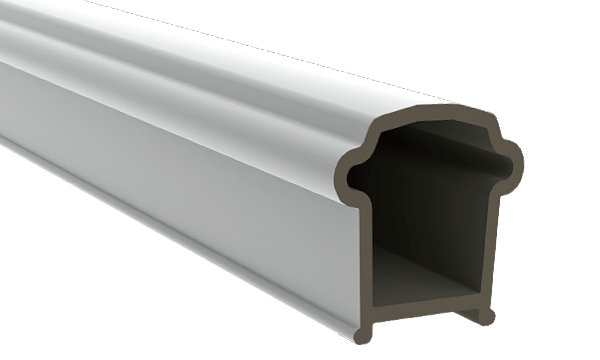

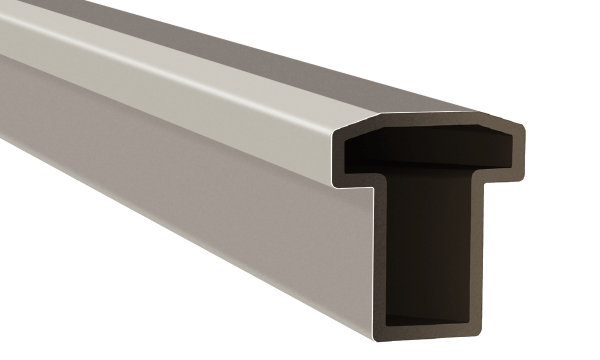

Compass Aluminum Railing posts are available in residential grade or commercial grade. Posts are available for where the top rail nests between the posts (2 1/2″ posts or 4 1/4″ posts)

Compass Aluminum Railing panels and top rails are 1/2″ shorter than the nominal dimension. This is to allow room for the mounting brackets and rail end caps. For example, an 8’ x 36″ panel is actually 95 1/2″ long. Once installed, accounting for bracket size, space between posts will be 96″.

Yes, but only when the stair section is level (0 degrees). Aluminum stair rail panels are designed for installation at angles ranging from 0 to 38 degrees. The higher the pitch of the rail, the closer together the spacing becomes. At maximum pitch, baluster spacing becomes about 3”.

Yes, MoistureShield railing products meet or exceed all code requirements for installation on second story levels. It is important to always check with your local code enforcement office for the requirements on your project.

Post caps can be glued in place with any vinyl adhesive. You may also use PVC glue or silicone adhesives that are sold at most hardware stores, lumber yards or home centers.

- Traverse Railing level rail kits are designed to install up to a 5-degree slope, which is the maximum pitch allowed by code.

- Discovery Railing level rail kits are designed to install up to a 5-degree slope, which is the maximum pitch allowed by code. A vinyl or PVC shim will be needed to shim the level brackets to match the slope of the ramp.

- Navigator Railing kits can accommodate handicap access ramps. This can be accomplished by purchasing a stair or beam kit with stair balusters and then cutting the rails and balusters to fit the 5-degree slope.

Yes, but only when the stair section is level (0 degrees). Stair rail panels are designed for installation at angles ranging from 0 to 41 degrees. The higher the pitch of the rail, the closer together the spacing becomes. At maximum pitch, baluster spacing becomes about 3”.

- Traverse Railing kits are 1/4″ shorter than the nominal dimension. For example, an 8’ x 36″ kit is actually 95 3/4″ long. Once installed, accounting for bracket size, space between posts will be 96″.

- Discovery Railing kits are 4 3/8″ shorter than the nominal dimension. For example, an 8’ x 36″ kit is actually 91 1/8″ long. Once installed, accounting for bracket size, space between posts will be 92″, and spacing from center of 4” posts will be 96”.

- Navigator Railing kits are true to the nominal length. For example, an 8’ x 36″ kit or top rail is actually 96″ long.

MoistureShield railing’s 4″ x 4″ adjustable vinyl post wraps are designed to fit posts ranging from 3 3/8″ to 4 1/8″ in size. In addition, MoistureShield railing’s 6″ x 6″ adjustable vinyl post wraps are designed to fit posts ranging from 5 7/16″ to 6 1/8″ in size.

It is NOT recommended to paint Discovery™ or Traverse™ railing. Painting will void the warranty these products. Navigator Railing features an acrylic cap which can be painted since it contains no plasticizers or additives that would interfere with paint adhesion or affect the paint’s durability. It is important that the paint used be specifically designed for acrylic surfaces. Ordinary house paint and traditional water-based paint will not adhere properly to acrylic. To ensure paint is suitable for acrylic, consult the paint manufacturer.

For normal cleaning, any non-abrasive cleaner mixed with water will be sufficient. For more stubborn problems, a magic eraser works well.

Some chalking is to be expected with any pigmented surface. Due to TiO2 performance, chalking will be at a minimum and will be washed away by normal weather conditions.

No, it will not. MoistureShield composite railing contains titanium dioxide (a UV inhibitor) which prevents ultraviolet degradation. MoistureShield Railing products are backed with a Transferable Limited Lifetime Warranty.

Most materials expand and contract with temperature changes. Our composite railing is engineered with this in mind.

Most plastics — composite included — become less flexible in cold weather. Under normal use, composite railing will not break when installed properly.

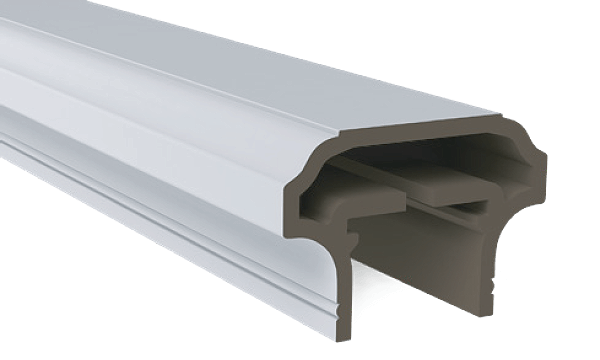

The base ingredient used for composite railing is rigid PVC (polyvinyl chloride), modified to provide superior strength and ultraviolet (UV) resistance. The formulation is similar to vinyl siding which has a nearly 30-year history of durability and structural integrity.

You may contact us through this website, contact our Customer Service Department at 866-729-2378 or via email at mscustomerservice@oldcastle.com.

Yes. However, every application is different. You should contact the Customer Service Department at MoistureShield for guidance. The warranty does not cover the product after it has been altered in this way.

MoistureShield has the same reaction to solvents and solutions as plastic surfaces. Therefore, ACQ will not harm MoistureShield.

The rating varies depending on the exact profile of the board. Please review the technical documents for each specific product. Note: Always defer to your local building codes before making a final decision.

No. Note: Always defer to your local building codes before making a final decision.

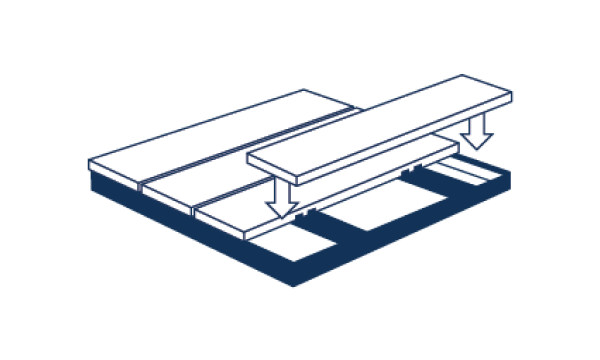

No. Deck planks must be installed with the correct spacing (see installation guide) to allow for water drainage, airflow, and the normal expansion and contraction of the various building materials used on any overall outdoor structure.

For Vantage products, we recommend 2 ¼” #7 trim head stainless steel screws. Counter-sink them 1/8 inch, run your thumb slightly over the hole, and use a hammer to lightly tap the product over the screw. For Vision, we suggest a color match screw or a plug system. Hidden fastening systems are the best way to avoid mushrooms and screws.

Many fasteners will work to achieve the minimum hold down force. When using MoistureShield products, it is advisable to also use a fastener that will do the same, such as stainless steel. These types of fasteners are also less likely to cause stains. MoistureShield boards can be face screwed or fastened using a hidden fastener. Feel free to call our Customer Service Department at 866-729-2378 for more information. Note: Always defer to your local building codes before making a final decision.

MoistureShield can be easily installed with standard woodworking tools, including a hammer, skill saw, rasp, level, and square. Standard carbide saw blades with less than 20 teeth are recommended. Please use blue chalk since other colored chalk may temporarily stain the deck.

The sub-structure is holding the weight, not the decking. If the application is installed on legs, i.e., grills or cabinets on rollers, contact MoistureShield at 866-729-2378 to determine feasibility.

Installation instructions are available on this website, or you can call our Customer Service Department at 866-729-2378.

Yes. When a product such as MoistureShield decking and accessories is made from recycled materials, the entire environmental waste spectrum is positively impacted. The recycled content in MoistureShield results in reduced energy consumption, reduced landfill waste, reduced hazardous waste, reduced air emissions, including greenhouse gases, reduced water consumption, and reduced wastewater.

Yes. MoistureShield is manufactured to specific standard construction dimensions and has no wane, knotholes, or other bad spots that require cutouts and create waste.

MoistureShield is always looking for ways to reduce the packaging burden and is careful to ensure that the packaging used is 100% recyclable.

Yes. Because MoistureShield is made with 95% recycled content, the fuel consumed during the extraction and processing of virgin raw materials is eliminated. As a result, a large part of the energy savings associated with recycling polyethylene comes from the reduction of fuel use during these two stages.

Yes. MoistureShield products are made with a mixture of recycled polyethylene plastic and recycled wood. Recycling one pound of wood conserves approximately 8,500 Btu’s of energy. Similarly, recycling one pound of polyethylene conserves approximately 28,350 Btu’s of energy. Consequently, building a 12′ x 12′ deck with MoistureShield saves an amount of energy roughly equal to 110 gallons of gasoline.

Yes. Since MoistureShield decking and accessories are made with 95% recycled content, water consumption is reduced or eliminated in the raw material extraction and processing stages that similar virgin-based products would experience.

Yes. MoistureShield decking and accessories are made with 95% recycled materials, of which 38% are post-consumer in origin.

MoistureShield decking can be installed using common woodworking tools, as all MoistureShield products can be cut and ripped without the need to seal the fresh cut surface. Vantage products can also be rasped and routed as there is no surface cap. Use a carbide blade with the smallest number of teeth possible (fewer than 20 is recommended) to avoid excessive heat, which can lead to a rough cut.

Yes. MoistureShield decking and accessories contain no added arsenic or other preservatives that are likely to be toxic under normal exposure conditions. Conventional wood treating processes impregnate the wood substrate with toxic chemicals to prevent rot and decay. MoistureShield is naturally resistant to rot and decay without toxic additives.

No. MoistureShield products are some of the least toxic products in the building industry. See the SDS document for details.

No. Polyethylene is non-toxic and is used for applications such as milk jugs, water jugs and grocery sacks. When burned completely, it will convert to carbon dioxide and water vapor.

MoistureShield has a class C fire rating which is the same as wood.

The entire MoistureShield product portfolio meets or exceeds OSHA’s recommendation of 0.5 for slip resistance. Vantage products have the best slip resistance; Vision products have better slip resistance.

Yes, using no more than 1300 PSI and keeping the wand at least 8 to 10 inches from the surface. Cleaning instructions are available on the website, or you can call our Customer Service Department at 866-729-2378.

Use a broom or leaf blower every few weeks. Use hot water, a good dish soap and a soft brush every six months. The best time to clean is after installation and semi-annually (spring and fall) to remove any debris. If stains persist, additional cleaning tips can be found on the care and cleaning page.

All MoistureShield products are stain-resistant. Some products also have a stain warranty (see warranty for details). Most stains commonly encountered, such as mustard and ketchup, will wash away easily. More stubborn stains can be washed off with the proper cleaner. Please call Customer Service at 866-729-2378 regarding stain cleaning. Recommended cleaners are listed here as well.

No, paint and stain are not recommended as it will not adhere to MoistureShield products and will void any existing fade & stain warranty associated with the product.

Each series offers unique features to help ensure your decking stays as beautiful as the day it was installed. In the event a board is damaged, the best action is to replace the affected board.

Vision products have the best color retention with a 50-Year fade warranty. See warranty document for details. Vantage products will fade like real wood since they are approximately 50% real wood and therefore do not have a fade warranty. Over time, UV rays from the sun will fade ANY outdoor product.

It would depend on the type of stain and type of decking. Cleaning instructions are available on this website, or you can call our Customer Service Department at 866-729-2378.

MoistureShield products will withstand the most hostile environment, including incidental saltwater contact or spray in coastal areas. At the foundation of every board is its solid core — an impermeable barrier that fights damage from moisture, rot, insects and other harmful elements. The Solid Core Difference is the key to MoistureShield’s durability and long life in difficult environments. In all environments, stainless steel screws are recommended.

Any surface will show evidence of normal wear and tear. Scuffs and scratches should be no problem as MoistureShield is a dense product. The Vision line offers our strongest capped wood composite board and is protected with our exclusive DiamondDefenseTM Coating to resist scratches, stains and damage on impact. Vantage products have self-healing properties, making scratches and scuffs less severe and noticeable over time through exposure to heat and sunlight.

No. MoistureShield has been extensively tested under hostile accelerated aging conditions by outside laboratories. It is warranted to resist rot and fungal decay when properly installed and maintained. See our warranty for details.

No. MoistureShield is virtually impervious to moisture and does not require pressure treatment, preservative treatments, water sealing or staining.

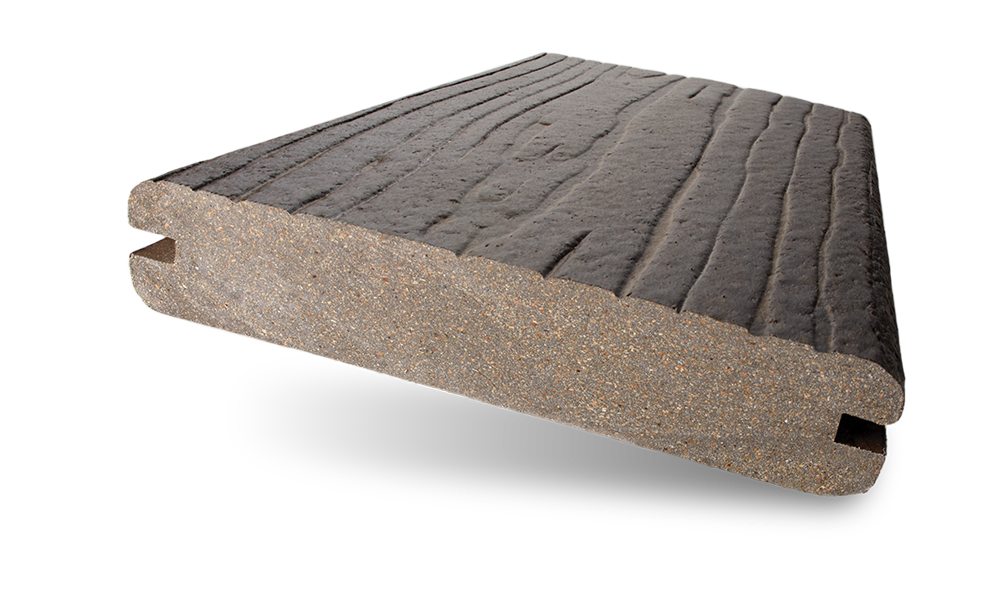

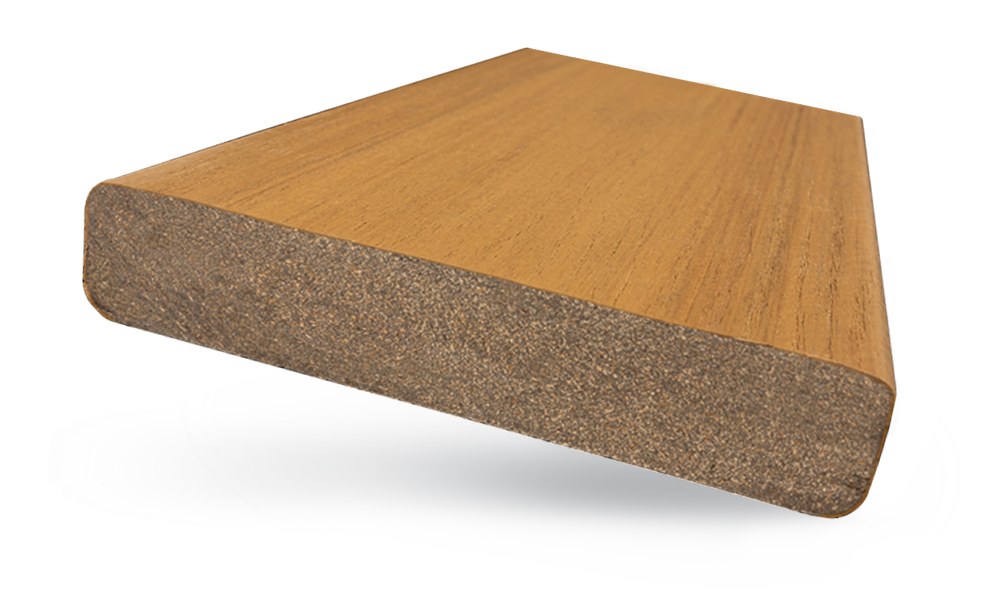

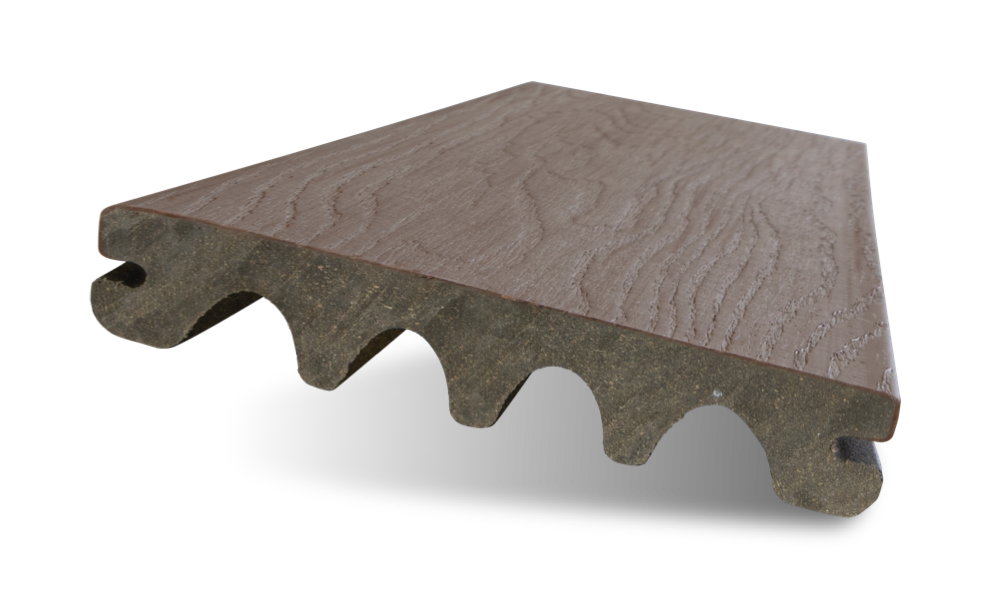

Because of our total encapsulation, our products are manufactured under several unique patents wherein the wood fibers are aligned and encapsulated in plastic. The plastic surrounds and bonds to the wood fibers, making them moisture resistant.

Yes, MoistureShield can be installed on the ground, in contact with the ground, on the water and under water. Learn more.

You can request a free sample through our website. You can also find local stocking and special-order dealers, as well as contractor installation partners under Where to Buy.

Our products have a solid core that allows them to be installed with ground and/or water contact, and they have stood up to the elements for more than 30+ years with no structural field failures. This attribute allows for a 50-year transferable structural warranty and applies across all our composite decking lines. Check the warranty information, as some products also have aesthetic level warranties for fade and stain, in addition to the structural warranty.

MoistureShield is manufactured under several unique patents in a process wherein wood fibers are aligned and encapsulated in plastic. The plastic surrounds and bonds to the wood fibers, making them virtually moisture-proof. The wood fibers reinforce the plastic, making it stiffer and greatly reducing its thermal movement. MoistureShield decking planks are extruded and allowed to cure slowly, which means the boards will not twist or warp. To learn more, check out Why MoistureShield.

All MoistureShield products are proudly made in the USA, in Springdale, Arkansas.

MoistureShield composite decking products are made of recycled wood fiber and polyethylene plastic.

Founded in 1988 as AERT, we pioneered the use of recycled polyethylene plastic in the manufacturing of composite building materials.